The Evolution of Digital Twins in Modern Manufacturing

Understanding Digital Twins: A Fundamental Concept

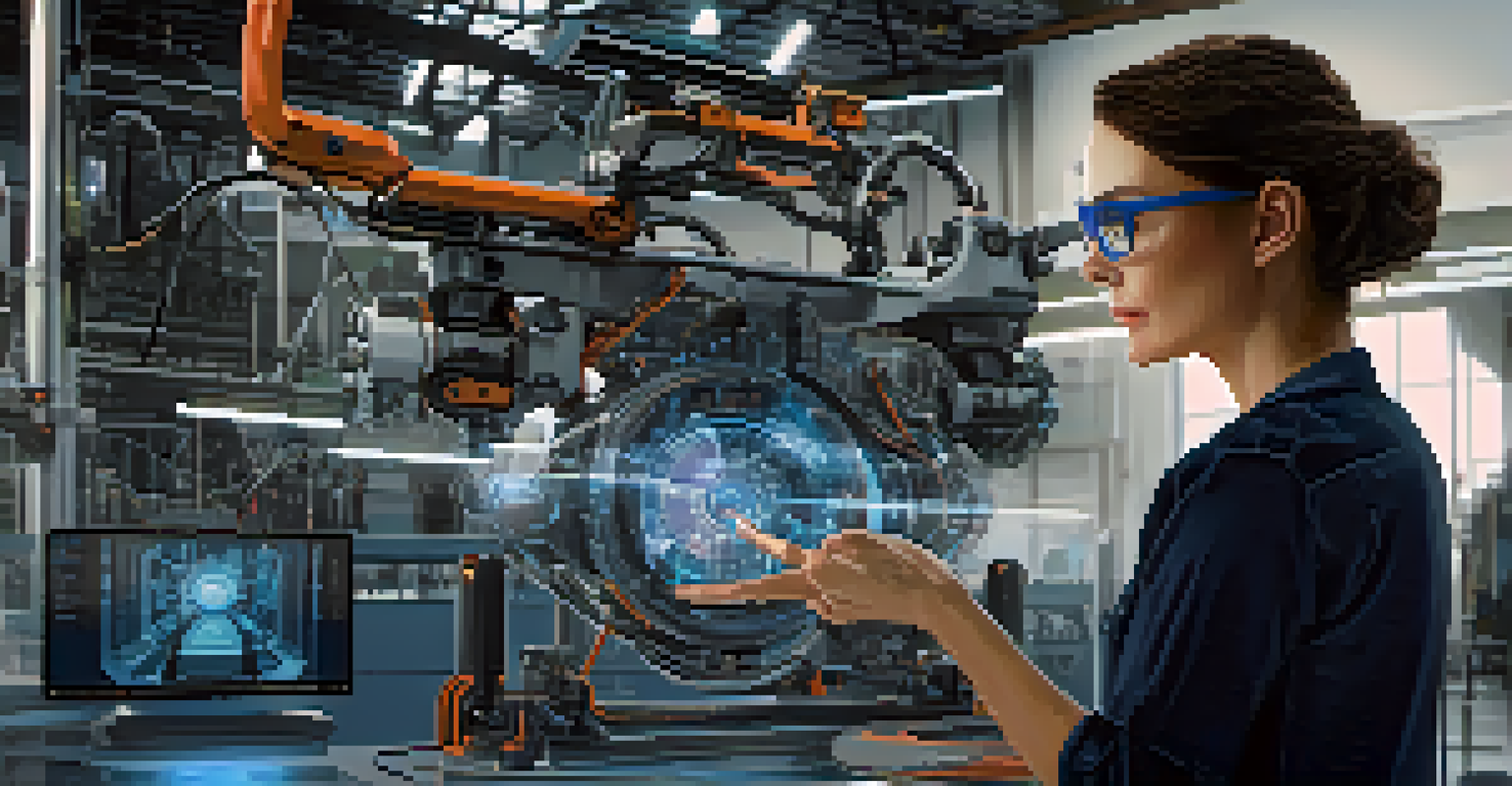

At its core, a digital twin is a virtual replica of a physical object or system. Think of it like a digital shadow that mirrors everything happening in the real world. This concept allows manufacturers to monitor, analyze, and optimize their operations in real time, making it easier to spot inefficiencies or potential issues before they escalate.

A digital twin is not just a representation of the physical world; it is a tool that provides valuable insights into how to optimize performance and efficiency.

The use of digital twins has grown significantly, especially with advancements in IoT (Internet of Things) technology. As sensors and data collection methods have improved, the ability to create accurate digital twins has become more feasible. This evolution means that manufacturers can now gather vast amounts of data that feed into these digital models, enhancing their accuracy and usefulness.

In essence, digital twins bridge the gap between the physical and digital worlds. By providing a dynamic representation of manufacturing processes, they enable businesses to simulate scenarios, test solutions, and ultimately improve decision-making.

The Historical Context of Digital Twins

The concept of digital twins isn't entirely new; it has its roots in the aerospace and automotive industries. Initially, these industries used simple models to predict performance and outcomes. Over time, as technology progressed, the models evolved into more complex digital representations, paving the way for broader applications in manufacturing.

As we entered the 21st century, the rise of big data and advanced analytics transformed how businesses approached modeling. Manufacturers began to realize the potential of integrating digital twins into their operations, which led to a surge in interest and investment. This historical backdrop showcases the importance of technological advancements in the evolution of digital twins.

Digital Twins Enhance Manufacturing

Digital twins serve as virtual replicas of physical systems, allowing manufacturers to monitor and optimize operations in real time.

The journey from simple models to sophisticated digital twins reflects a broader trend in manufacturing: the shift towards data-driven decision-making. This transformation has not only improved efficiency but has also fostered innovation across various sectors.

Key Technologies Driving Digital Twin Development

Several key technologies have played a crucial role in the development of digital twins. One of the most significant is the Internet of Things (IoT), which enables devices to connect and communicate, collecting real-time data. This data is vital for creating accurate digital representations of physical assets and processes.

The future of manufacturing is not just about products; it's about the data that drives those products and the digital twins that help us understand them.

Another important technology is cloud computing, which allows for the storage and processing of large data sets generated by IoT devices. With cloud capabilities, manufacturers can access their digital twins from anywhere, facilitating collaboration and real-time updates. This accessibility has made digital twins even more indispensable in modern manufacturing environments.

Lastly, advancements in artificial intelligence (AI) and machine learning have enhanced the predictive capabilities of digital twins. By analyzing historical data, these technologies can provide insights into potential future outcomes, allowing manufacturers to proactively address challenges before they arise.

Applications of Digital Twins in Manufacturing

Digital twins have a multitude of applications in manufacturing, ranging from process optimization to predictive maintenance. For instance, manufacturers can simulate production processes to identify bottlenecks or inefficiencies, leading to smoother operations and increased productivity. This proactive approach to manufacturing helps businesses stay competitive in a rapidly evolving market.

Predictive maintenance is another area where digital twins shine. By continuously monitoring equipment performance, manufacturers can predict when machinery is likely to fail, allowing them to schedule maintenance before an issue disrupts production. This approach not only saves costs but also minimizes downtime, enhancing overall operational efficiency.

Challenges in Digital Twin Adoption

Implementing digital twins can be hindered by issues such as integrating legacy systems, ensuring data quality, and addressing skill gaps in the workforce.

Moreover, digital twins can support product design and development by allowing teams to test various scenarios virtually. This capability reduces the need for physical prototypes, accelerating innovation and reducing costs associated with traditional development processes.

Challenges in Implementing Digital Twins

While the benefits of digital twins are clear, implementing them comes with its challenges. One significant hurdle is the integration of existing systems and data sources. Many manufacturers have legacy systems that may not easily connect with new digital twin technologies, leading to potential data silos and inefficiencies.

Additionally, the need for high-quality data cannot be overstated. Inaccurate or incomplete data can lead to flawed digital twins, undermining the value they bring. Manufacturers must invest in data management practices and ensure that they gather reliable information to maintain the integrity of their digital twins.

Lastly, there’s the challenge of skill gaps within the workforce. As digital twin technology evolves, there is a growing need for employees who are well-versed in data analytics, IoT, and digital modeling. Organizations must prioritize training and development to equip their teams with the necessary skills to leverage digital twins effectively.

The Future of Digital Twins in Manufacturing

Looking ahead, the future of digital twins in manufacturing is incredibly promising. As technology continues to advance, we can expect digital twins to become even more sophisticated, incorporating augmented reality (AR) and virtual reality (VR) for enhanced visualization. These technologies could further bridge the gap between the physical and digital worlds, making it easier for manufacturers to understand and optimize their operations.

Moreover, the growing emphasis on sustainability will likely drive the adoption of digital twins. Manufacturers can use these digital models to simulate environmental impacts and optimize resource use, aligning with the increasing demand for eco-friendly practices. This trend will not only benefit the planet but also enhance brand reputation and consumer trust.

Future Innovations with Digital Twins

The future of digital twins in manufacturing looks bright, with potential advancements in augmented reality, sustainability efforts, and new business models.

Finally, as industries increasingly adopt digital twins, we may witness new business models emerging. Companies could offer services based on real-time data analytics derived from digital twins, creating new revenue streams and fostering collaboration across the supply chain.

Conclusion: Embracing Digital Twins for Competitive Advantage

In conclusion, the evolution of digital twins in modern manufacturing represents a significant shift towards data-driven decision-making and operational excellence. As manufacturers embrace this technology, they can unlock numerous benefits, from improved efficiency to enhanced predictive capabilities. It's clear that digital twins are not merely a trend; they are a vital tool for staying competitive in today's fast-paced market.

By understanding the historical context and key technologies driving digital twin development, manufacturers can better navigate the challenges and seize the opportunities this technology presents. As we move into a future where digital twins become more integrated into everyday manufacturing processes, the potential for innovation and growth is limitless.

Ultimately, embracing digital twins is about more than just technology; it's about fostering a culture of continuous improvement and adaptability. By doing so, manufacturers can position themselves for success in an ever-evolving industrial landscape.