The Impact of Digital Twins on Product Lifecycle Management

Understanding Digital Twins: A Brief Overview

Digital twins are virtual replicas of physical objects, processes, or systems. They mirror real-world counterparts in real-time, allowing for data-driven insights and analysis. Think of it as having a digital shadow that reflects the behavior and characteristics of its physical twin.

The digital twin is a revolutionary technology that has the potential to transform the way we design, manufacture, and manage products throughout their lifecycle.

This technology has gained traction across various industries, from manufacturing to healthcare, enabling better decision-making and improved outcomes. By using sensors and IoT, digital twins collect and analyze data to simulate performance, anticipate failures, and suggest optimizations.

In essence, digital twins serve as a bridge between the physical and digital worlds, enhancing our ability to understand and manage products throughout their lifecycle.

The Role of Digital Twins in Product Design

During the product design phase, digital twins can significantly streamline the process. Designers can create and test virtual models before committing to physical prototypes, saving time and resources. Imagine being able to tweak your design in a virtual environment without the costs associated with physical changes.

This iterative process allows teams to identify potential flaws early and make informed decisions based on real-time data and simulations. As a result, products can be optimized for performance and user experience before they even hit the market.

Digital Twins Enhance Design Efficiency

They allow designers to create and test virtual models, streamlining the product design process and reducing costs.

Ultimately, digital twins empower designers to innovate more freely, resulting in products that better meet customer needs and expectations.

Enhancing Manufacturing Processes with Digital Twins

In manufacturing, digital twins are game-changers for optimizing production processes. By creating a digital representation of the manufacturing system, companies can monitor operations in real time and identify inefficiencies. It's like having a dashboard that shows how everything is running.

In the age of digital transformation, digital twins offer a new lens through which we can gain insights and optimize our processes.

With predictive analytics, manufacturers can foresee potential disruptions and schedule maintenance proactively. This not only reduces downtime but also extends the lifespan of machinery and equipment, ultimately leading to cost savings.

By leveraging these insights, businesses can enhance productivity and ensure a smoother manufacturing process, making digital twins an invaluable tool in modern production landscapes.

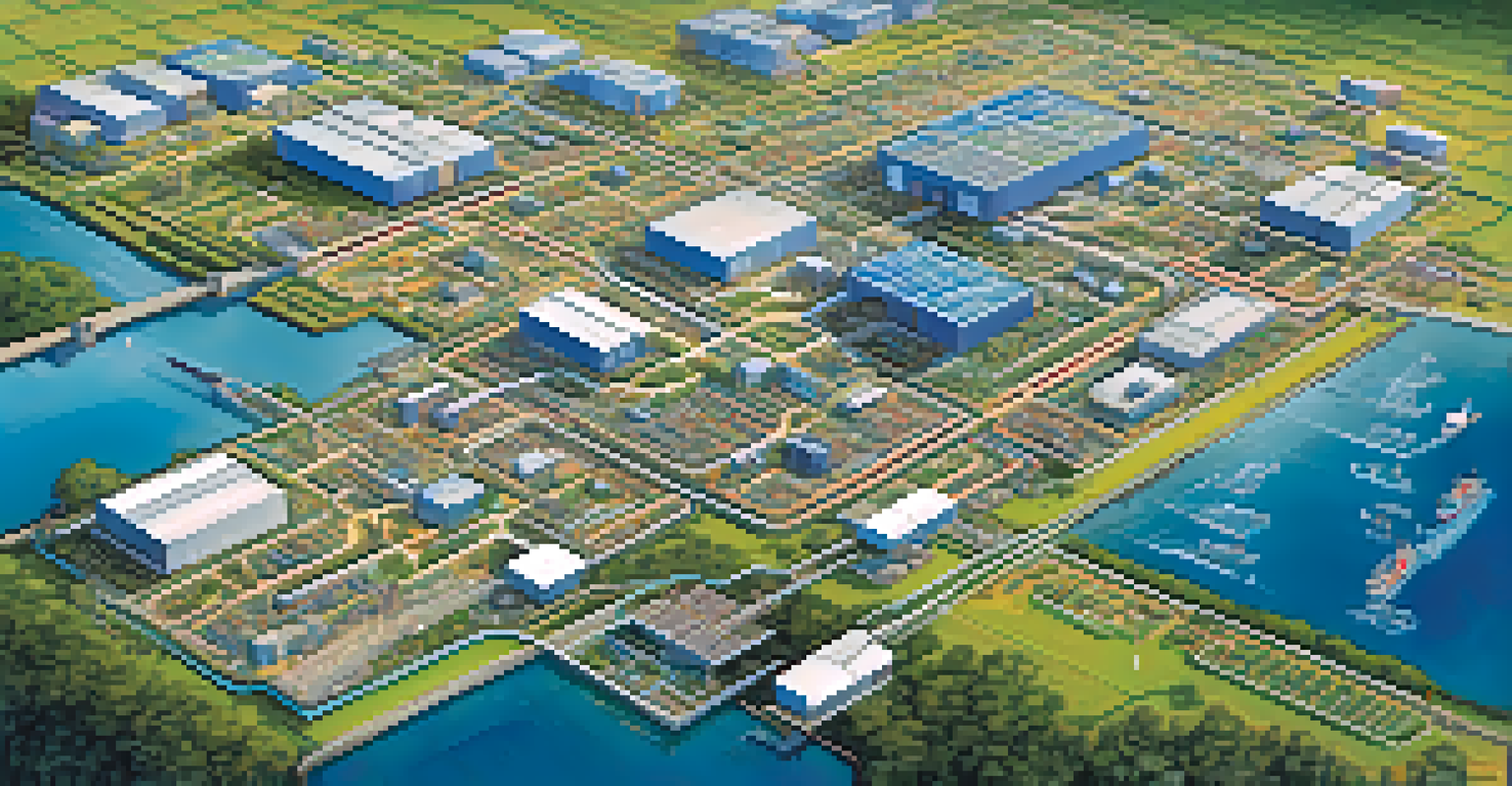

Digital Twins and Supply Chain Optimization

Digital twins play a crucial role in managing and optimizing supply chains. By simulating the entire supply chain process, organizations can identify bottlenecks and improve logistics. This holistic view is akin to having a bird's-eye view of your entire supply chain dynamics.

Through real-time data analysis, companies can adjust inventory levels, forecast demand, and respond swiftly to market changes. This agility can significantly enhance customer satisfaction and reduce operational costs.

Boosting Manufacturing Productivity

Digital twins optimize manufacturing by providing real-time data and predictive analytics to identify inefficiencies.

In essence, digital twins facilitate a smarter, more responsive supply chain, allowing businesses to adapt quickly and efficiently.

Improving Product Performance Monitoring with Digital Twins

One of the standout advantages of digital twins is their ability to monitor product performance throughout its lifecycle. Sensors gather data on how products function in real-world conditions, providing insights into their durability and efficiency. Think of it as having a constant check-up on a product’s health.

By analyzing this data, companies can identify issues before they escalate into significant problems, allowing for timely interventions. This proactive approach not only enhances product reliability but also builds customer trust.

As a result, manufacturers can provide improved after-sales support and make data-driven decisions for future product iterations.

The Impact of Digital Twins on Product Lifecycle Sustainability

Sustainability is a growing concern in product lifecycle management, and digital twins offer solutions to minimize environmental impact. By simulating various scenarios, organizations can evaluate the sustainability of their products and processes. It’s like doing a virtual stress test on your product’s ecological footprint.

This insight enables companies to design products that are not only efficient but also environmentally friendly. From reducing waste during manufacturing to optimizing energy consumption, digital twins pave the way for greener practices.

Sustainability Through Simulation

By evaluating sustainability scenarios, digital twins help organizations design environmentally friendly products and practices.

Ultimately, this focus on sustainability not only benefits the planet but also enhances a brand's reputation and appeals to environmentally conscious consumers.

Challenges and Considerations in Implementing Digital Twins

While the benefits of digital twins are clear, implementing this technology does come with challenges. Organizations must consider the integration of existing systems, data management, and the necessary investment in technology and training. It’s essential to approach this transition strategically to avoid potential pitfalls.

Additionally, ensuring data security is paramount, as digital twins rely on vast amounts of sensitive information. Companies need to establish robust cybersecurity measures to protect their data and maintain customer trust.

By addressing these challenges head-on, organizations can successfully harness the power of digital twins and transform their product lifecycle management.

The Future of Digital Twins in Product Lifecycle Management

Looking ahead, the potential for digital twins in product lifecycle management is immense. As technology advances, we can expect increased integration with artificial intelligence and machine learning, leading to even smarter systems. Imagine a future where your digital twin not only reflects reality but also predicts outcomes based on historical data.

This evolution will enable companies to make rapid adjustments and continuously improve their products and processes. The synergy between digital twins and emerging technologies could redefine how we approach product development and lifecycle management.

In conclusion, the future is bright for digital twins, promising enhanced efficiency, sustainability, and innovation in product lifecycle management.